In the global public health arsenal, few tools have proven as universally cost-effective, scalable, and impactful as the mosquito net. For over two decades, the widespread distribution of Long-Lasting Insecticidal Nets (LLINs) has served as the undisputed first line of defense against malaria, a disease that has plagued humanity for millennia. The statistics speak to a public health triumph: LLINs are credited with preventing over 1 billion malaria cases and saving nearly 7 million lives since the year 2000, primarily among children under five and pregnant women in sub-Saharan Africa. However, declaring victory would be premature; the battlefield is constantly shifting. The fight against vector-borne diseases is evolving at a rapid pace. The relentless selection pressure from pyrethroid insecticides has led to the widespread emergence and geographic spread of insecticide-resistant mosquito populations, while operational challenges in harsh field conditions demand greater physical durability from the nets themselves. These dual threats—biological and mechanical—are driving a new wave of profound innovation in net design, material science, and insecticide technology, ensuring this simple yet powerful tool evolves to remain a cornerstone of global disease prevention strategies in the 21st century.

The technological journey of the LLIN is a story of continuous improvement. The first generation relied on dipping polyester or polyethylene netting into a solution of a synthetic pyrethroid insecticide. The current generation, however, represents a significant leap forward in chemistry and manufacturing. The industry has largely transitioned from surface-level coating to sophisticated "incorporation" or "masterbatch" technology. In this process, the insecticide is directly embedded as a masterbatch within the polyethylene polymer granules before they are extruded into fibers. This fusion of material and chemistry is fundamental. It allows for a more controlled and sustained release of the active ingredient, which migrates from the core of the fiber to its surface over time, replenishing the insecticidal layer as it is worn away by friction or gentle washing. The result is a net that remains lethally effective against susceptible mosquitoes for up to three years under field conditions, or through 20 standardized washes, far outperforming the longevity and reliability of earlier models. Polyethylene has become the material of choice for this purpose due to its unique combination of versatility, cost-effectiveness at a massive global scale, and its polymer matrix's unique ability to act as an efficient reservoir for the incorporated insecticides.

The formidable and growing challenge of pyrethroid resistance is now being met with a multi-pronged technological counter-offensive, marking the most critical evolution in LLIN technology in a decade. The most significant development is the global rollout of "next-generation" or "dual-active ingredient" LLINs. These nets feature a combination of insecticides with entirely different modes of action, creating a powerful synergistic effect. One prominent type combines a standard pyrethroid (which targets the mosquito's nervous system) with an Insect Growth Regulator (IGR) like Pyriproxyfen. The IGR does not kill the adult mosquito directly but is transferred when the mosquito lands on the net; it then inhibits the development of eggs and larvae, effectively sterilizing the female and reducing the local mosquito population over time. Another type pairs a pyrethroid with a completely different class of insecticide, such as Chlorfenapyr (a pyrrole), which disrupts the mosquito's cellular energy production. Because the modes of action are distinct, it is exponentially more difficult for a mosquito population to develop resistance to both chemicals simultaneously, effectively restoring the net's killing power in resistant areas.

Alongside this chemical arms race, the physical design and architecture of the nets are undergoing rigorous re-evaluation and optimization. Durability is now recognized as a Key Performance Indicator (KPI) of effectiveness, on par with insecticidal potency. The World Health Organization (WHO) and partners have established the "Persistence" campaign to emphasize this, as a net that tears easily is a net that fails, regardless of its sophisticated chemical payload. Enhanced weaving techniques, such as using higher-denier (thicker) yarns or innovative knot structures, are being implemented to increase tensile strength and resistance to tearing. Some manufacturers are exploring blended yarns, combining polyester for its superior toughness with polyethylene for its insecticide incorporation capabilities. Furthermore, reinforced borders and seams are critical, as these are often the points of failure. Research is also ongoing into mesh size, shape (exploring hexagonal or triangular configurations versus standard rectangles), and porosity to find the perfect balance between creating an impenetrable physical barrier for even the smallest mosquitoes and ensuring optimal airflow for user comfort, which is a key determinant of consistent usage.

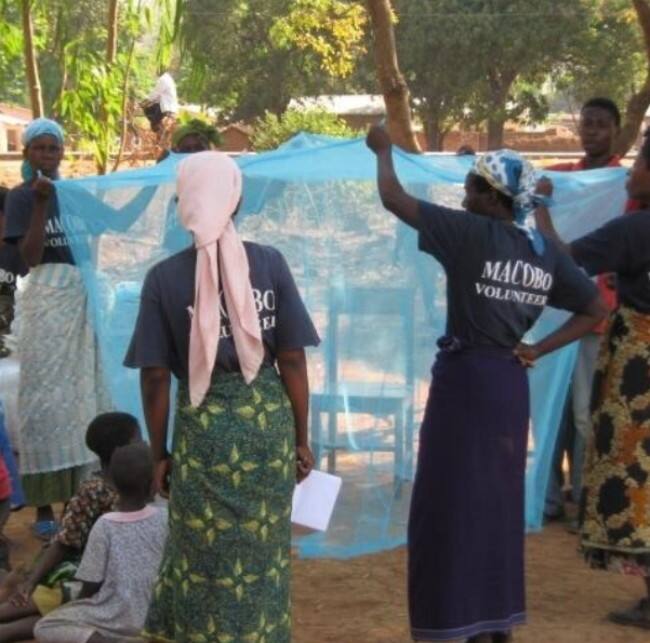

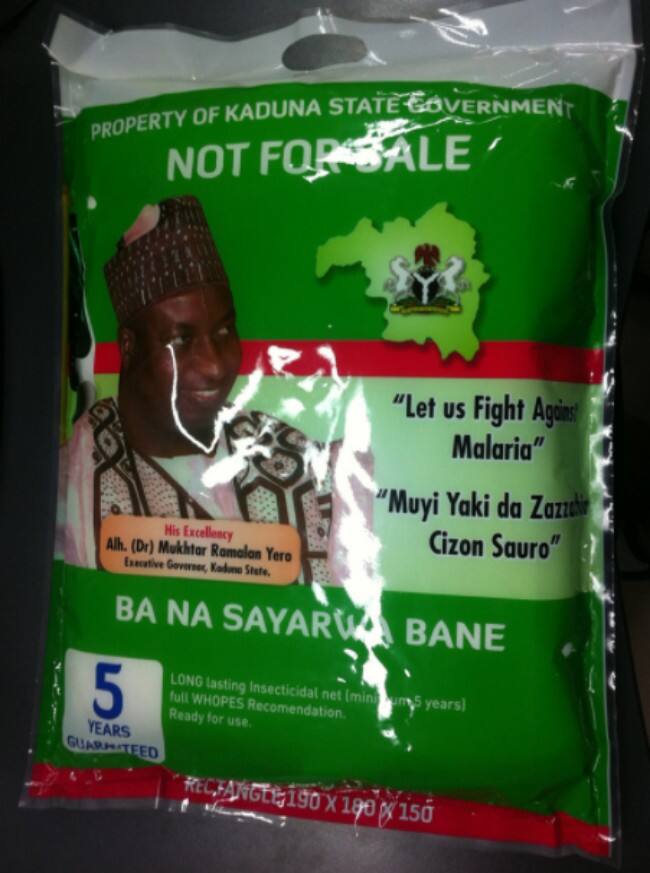

The distribution and, crucially, the consistent and correct use of these advanced nets remain the final, critical link in the chain. As a key supplier to major international aid organizations (like The Global Fund and UNICEF), NGOs, and national governments, our role extends far beyond manufacturing. We are actively involved in the entire ecosystem of net deployment. This includes creating clear, pictogram-based educational materials that transcend language barriers, advising on distribution logistics to prevent damage during transport and storage, and ensuring our packaging prominently displays simple, visual instructions for proper hanging, daily use, and gentle care (e.g., shaking off dust instead of harsh washing) to maximize the net's functional lifespan. The humble mosquito net has transformed from a simple piece of fabric into a sophisticated product of material engineering, polymer chemistry, entomology, and behavioral science. As the world continues its grueling fight against malaria and confronts the expanding global threat from Aedes-borne diseases like dengue, Zika, and Chikungunya, this continued, relentless innovation in mosquito net technology will be absolutely vital. It is our unseen shield, protecting vulnerable communities, strengthening overburdened healthcare systems, and moving us inexorably closer to the ultimate goal of a world free from the scourge of mosquito-borne diseases.